12 Expert Tips For Mastering Silver Specific Heat In 2024 Applications

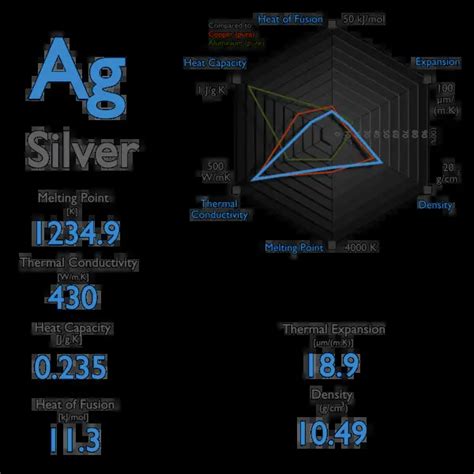

Silver, with its high thermal conductivity and specific heat capacity, is a crucial material in various industrial applications, including electronics, thermal management systems, and renewable energy technologies. The specific heat of silver, which is approximately 0.235 joules per gram per degree Celsius (J/g°C), plays a significant role in determining its performance and efficiency in these applications. As we move into 2024, mastering silver specific heat will be essential for optimizing the design and operation of numerous devices and systems. In this article, we will explore 12 expert tips for mastering silver specific heat in 2024 applications, highlighting the importance of precise calculations, material selection, and innovative design approaches.

Understanding Silver Specific Heat and Its Applications

Silver’s high specific heat capacity allows it to absorb and release large amounts of thermal energy without undergoing significant temperature changes. This property makes silver an ideal material for applications where efficient heat transfer and thermal management are critical, such as in thermal interface materials, heat sinks, and thermal energy storage systems. To master silver specific heat, it is essential to understand the underlying physics and chemistry of this material, including its thermal conductivity, specific heat capacity, and density.

Tip 1: Precise Calculation of Silver Specific Heat

To accurately calculate the specific heat of silver, it is crucial to consider the material’s purity, crystal structure, and temperature range. The specific heat of silver can be calculated using the following equation: C = Q / (m * ΔT), where C is the specific heat capacity, Q is the amount of heat transferred, m is the mass of the silver sample, and ΔT is the temperature change. By using this equation and considering the relevant factors, engineers can precisely calculate the specific heat of silver and optimize its performance in various applications.

| Property | Value |

|---|---|

| Specific Heat Capacity | 0.235 J/g°C |

| Thermal Conductivity | 429 W/m-K |

| Density | 10.49 g/cm³ |

Tip 2: Material Selection and Optimization

The selection of silver alloys and composites can significantly impact the specific heat capacity and overall performance of silver-based systems. By optimizing the material selection and composition, engineers can improve the thermal conductivity, mechanical strength, and corrosion resistance of silver, making it more suitable for various applications. For example, silver-copper alloys can exhibit improved thermal conductivity and mechanical strength compared to pure silver, while silver-tin alloys can offer enhanced corrosion resistance and solderability.

Advanced Applications of Silver Specific Heat

The unique properties of silver make it an ideal material for various advanced applications, including renewable energy systems, thermal energy storage, and electronics cooling. In these applications, mastering silver specific heat is crucial for optimizing system performance, efficiency, and reliability. By leveraging the high specific heat capacity and thermal conductivity of silver, engineers can design and develop innovative systems that can efficiently harness, store, and manage thermal energy.

Tip 3: Innovative Design Approaches

Innovative design approaches, such as additive manufacturing and nanotechnology, can enable the creation of complex silver structures and composites with tailored thermal properties. By using these design approaches, engineers can optimize the specific heat capacity and thermal conductivity of silver, making it more suitable for various applications. For example, silver-based nanocomposites can exhibit enhanced thermal conductivity and specific heat capacity compared to bulk silver, while additively manufactured silver structures can offer improved thermal management and mechanical strength.

Tip 4: Thermal Interface Materials

Thermal interface materials (TIMs) play a critical role in optimizing the thermal performance of silver-based systems. By selecting and designing optimal TIMs, engineers can minimize thermal resistance and maximize heat transfer, making it possible to efficiently manage thermal energy in various applications. Silver-based TIMs, such as silver-filled epoxies and silver-coated particles, can offer high thermal conductivity and reliability, making them ideal for use in electronics cooling and thermal energy storage systems.

Tip 5: Heat Sinks and Thermal Management

Heat sinks and thermal management systems are critical components in various applications, including electronics, renewable energy systems, and thermal energy storage. By mastering silver specific heat and optimizing heat sink design, engineers can efficiently manage thermal energy and minimize thermal resistance, making it possible to improve system performance, efficiency, and reliability. Silver-based heat sinks, such as silver-coated copper and silver-filled polymers, can offer high thermal conductivity and mechanical strength, making them ideal for use in various applications.

Tip 6: Thermal Energy Storage

Thermal energy storage systems, such as molten salt and phase change materials, rely on the high specific heat capacity of silver to efficiently store and release thermal energy. By optimizing the design and operation of these systems, engineers can improve their performance, efficiency, and reliability, making it possible to harness and utilize thermal energy more effectively. Silver-based thermal energy storage systems can offer high energy density and thermal conductivity, making them ideal for use in renewable energy systems and industrial processes.

Tip 7: Electronics Cooling

Electronics cooling systems, such as heat pipes and liquid cooling, rely on the high thermal conductivity of silver to efficiently manage thermal energy. By mastering silver specific heat and optimizing cooling system design, engineers can improve the performance, efficiency, and reliability of electronics, making it possible to increase their power density and operating frequency. Silver-based cooling systems, such as silver-coated heat pipes and silver-filled liquid coolants, can offer high thermal conductivity and reliability, making them ideal for use in high-performance electronics and data centers.

Tip 8: Renewable Energy Systems

Renewable energy systems, such as solar thermal and geothermal, rely on the high specific heat capacity of silver to efficiently harness and utilize thermal energy. By optimizing the design and operation of these systems, engineers can improve their performance, efficiency, and reliability, making it possible to increase the adoption of renewable energy technologies. Silver-based renewable energy systems can offer high energy density and thermal conductivity, making them ideal for use in concentrated solar power and enhanced geothermal systems.

Tip 9: Advanced Materials and Coatings

Advanced materials and coatings, such as nanomaterials and thin films, can enhance the thermal properties of silver, making it more suitable for various applications. By leveraging these materials and coatings, engineers can optimize the specific heat capacity and thermal conductivity of silver, making it possible to improve system performance, efficiency, and reliability. Silver-based nanomaterials and thin films can offer high thermal conductivity and mechanical strength, making them ideal for use in high-performance electronics and renewable energy systems.

Tip 10: Simulation and Modeling

Simulation and modeling tools, such as finite element analysis and computational fluid dynamics, can help engineers optimize the design and operation of silver-based systems. By using these tools, engineers can simulate the thermal behavior of silver and predict its performance in various applications, making it possible to improve system efficiency, reliability, and cost-effectiveness. Silver-based simulation and modeling can offer high accuracy and reliability, making them ideal for use in high-performance electronics and renewable energy systems.

Tip 11: Experimental Characterization

Experimental characterization techniques, such as thermal conductivity measurement and specific heat capacity measurement, can help engineers determine the thermal properties of silver and optimize its performance in various applications. By using these techniques, engineers can measure the thermal conductivity and specific heat capacity of silver, making it possible to improve system design, efficiency, and reliability. Silver-based experimental characterization can offer high accuracy and reliability, making them ideal for use in high-performance electronics</