Capability Index Formula

The Capability Index, also known as the Capability Ratio or Cpk, is a statistical measure used to assess the ability of a process to produce output within specified limits. It is a widely used metric in quality control and Six Sigma initiatives to evaluate the performance of a process. The Capability Index formula provides a quantitative measure of the process's ability to meet customer requirements and specifications.

Understanding the Capability Index Formula

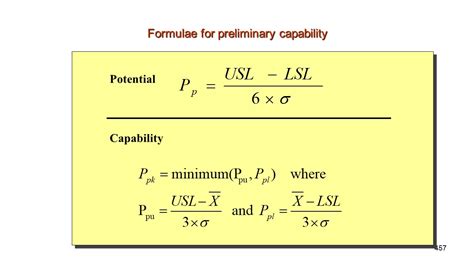

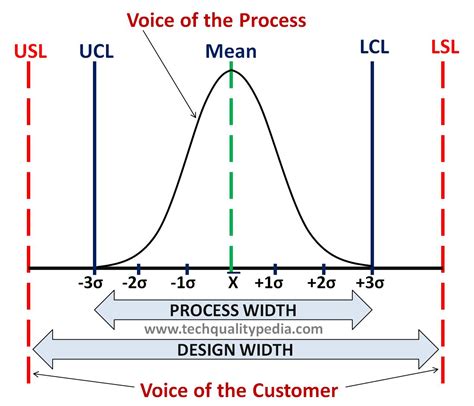

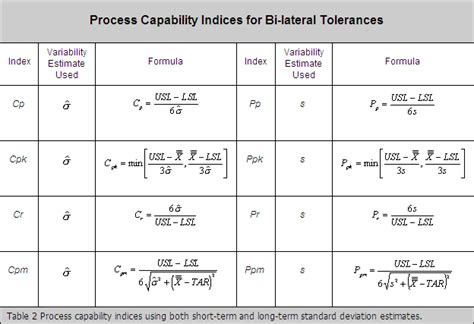

The Capability Index formula is calculated using the following equation: Cpk = min(CPU, CPL), where CPU = (USL - mean) / (3 * sigma) and CPL = (mean - LSL) / (3 * sigma). In this equation, USL represents the upper specification limit, LSL represents the lower specification limit, mean represents the process mean, and sigma represents the standard deviation of the process.

Breaking Down the Formula Components

The Capability Index formula consists of several key components, including the upper specification limit (USL), lower specification limit (LSL), process mean, and standard deviation. The upper specification limit is the maximum allowable value for a process, while the lower specification limit is the minimum allowable value. The process mean represents the average value of the process, and the standard deviation represents the amount of variation in the process.

The CPU (Capability Index for the upper limit) and CPL (Capability Index for the lower limit) are calculated separately and then compared to determine the overall Capability Index (Cpk). The minimum of these two values is used to determine the overall Cpk, as it represents the most limiting factor in the process.

| Capability Index Component | Description |

|---|---|

| CPU | Capability Index for the upper limit |

| CPL | Capability Index for the lower limit |

| USL | Upper specification limit |

| LSL | Lower specification limit |

| Mean | Process mean |

| Sigma | Standard deviation of the process |

Interpreting Capability Index Values

The Capability Index value provides a quantitative measure of the process’s ability to meet customer requirements. A higher Capability Index value indicates a more capable process, while a lower value indicates a less capable process. The following general guidelines are used to interpret Capability Index values:

- Cpk ≥ 1.33: The process is considered capable, with a low probability of producing defective products.

- 1.00 ≤ Cpk < 1.33: The process is considered marginal, with a moderate probability of producing defective products.

- Cpk < 1.00: The process is considered incapable, with a high probability of producing defective products.

Example Application of the Capability Index Formula

Suppose a manufacturer produces widgets with a specified length of 10 ± 0.5 inches. The process mean is 10.2 inches, and the standard deviation is 0.1 inches. To calculate the Capability Index, we need to determine the USL, LSL, and CPU and CPL values.

USL = 10.5 inches, LSL = 9.5 inches, CPU = (10.5 - 10.2) / (3 * 0.1) = 1.00, and CPL = (10.2 - 9.5) / (3 * 0.1) = 1.17. The Capability Index (Cpk) is the minimum of these two values, which is 1.00. Based on this value, the process is considered marginal, with a moderate probability of producing defective products.

What is the difference between Cpk and Ppk?

+Cpk and Ppk are both measures of process capability, but they differ in their calculation and application. Cpk is a measure of the process’s ability to produce output within specified limits, while Ppk is a measure of the process’s actual performance over a specific period. Cpk is typically used for short-term process capability, while Ppk is used for long-term process capability.

How do I improve the Capability Index of a process?

+To improve the Capability Index of a process, focus on reducing variation and centering the process mean. This can be achieved through various methods, such as process optimization, operator training, and equipment maintenance. Additionally, implementing statistical process control and continuous improvement initiatives can help to identify and address potential issues before they impact the process capability.