How To Calculate Capability Index For Advanced Statistical Process Control Easily

The capability index is a statistical measure used to assess the ability of a process to produce output within specified limits. It is a crucial metric in statistical process control (SPC) and is widely used in various industries, including manufacturing, healthcare, and finance. In this article, we will discuss how to calculate the capability index for advanced statistical process control easily.

Understanding Capability Index

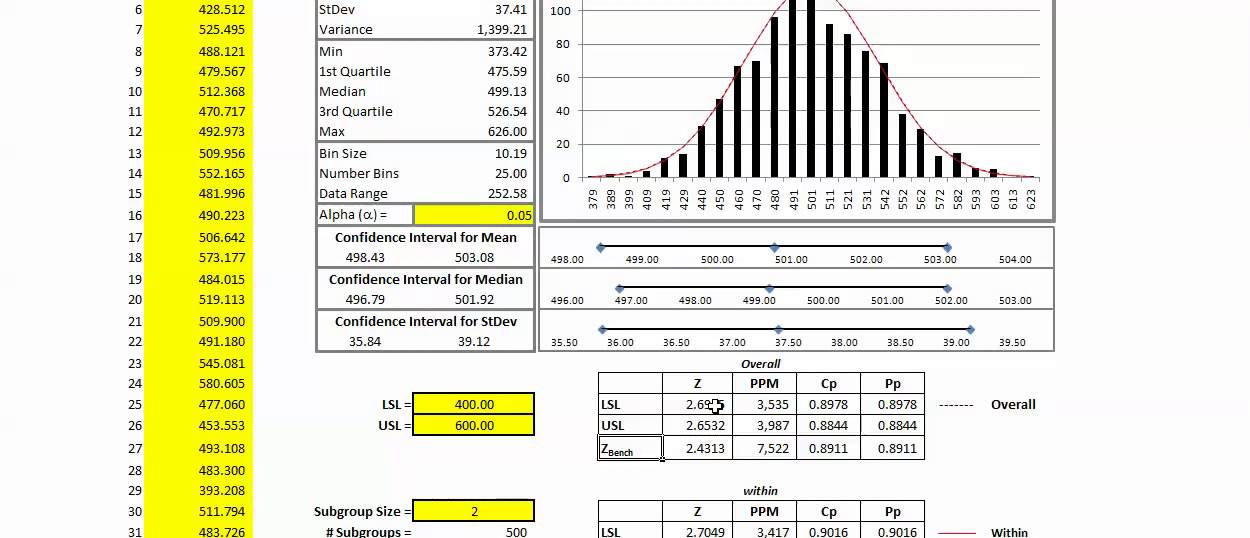

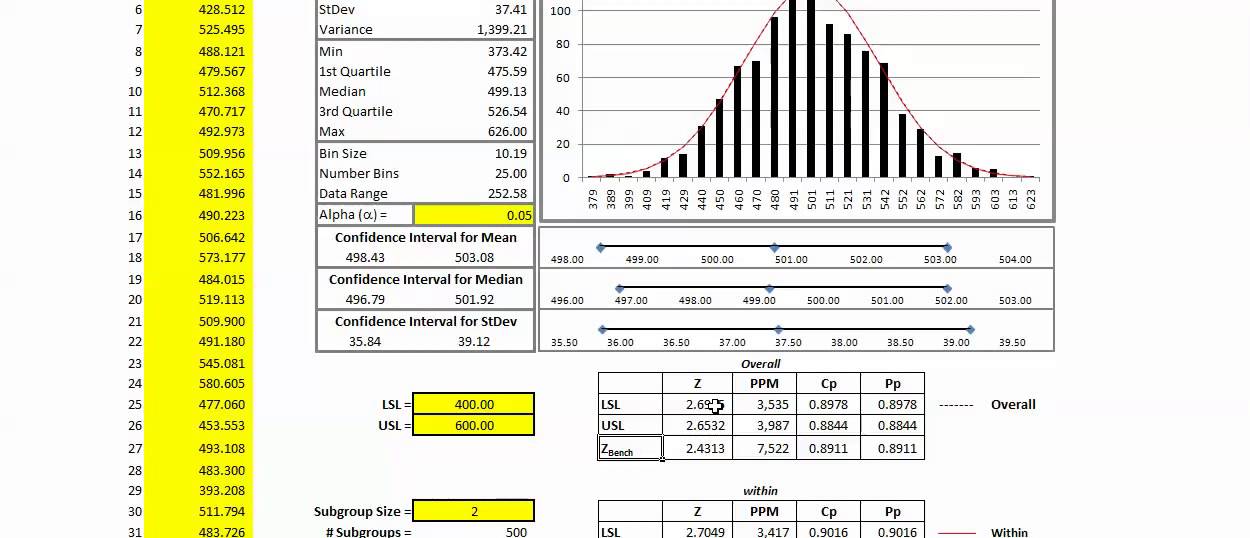

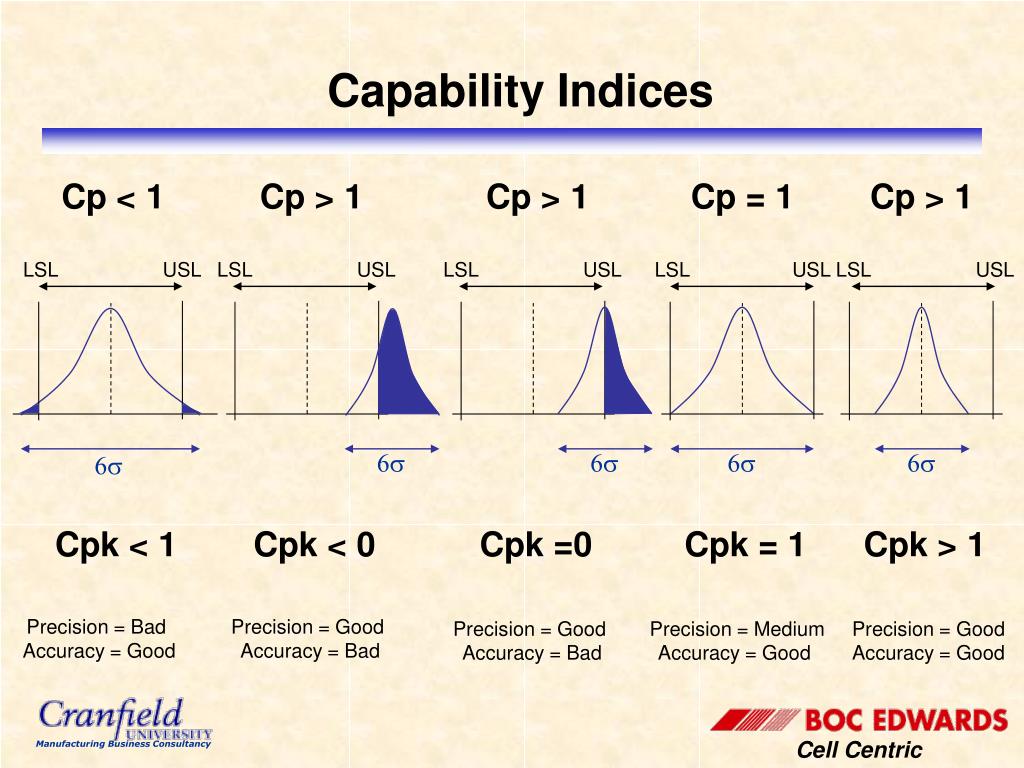

The capability index is a dimensionless quantity that represents the ratio of the specification width to the process width. It is calculated using the following formula: Cpk = min[(USL - μ) / 3σ, (μ - LSL) / 3σ], where USL is the upper specification limit, LSL is the lower specification limit, μ is the process mean, and σ is the process standard deviation. The capability index is a measure of the process’s ability to produce output within the specified limits, and it is used to determine the process’s capability to meet customer requirements.

Types of Capability Index

There are several types of capability index, including Cp, Cpk, and Cpm. Cp is the basic capability index, which is calculated using the formula: Cp = (USL - LSL) / 6σ. Cpk is the centered capability index, which takes into account the process mean and is calculated using the formula: Cpk = min[(USL - μ) / 3σ, (μ - LSL) / 3σ]. Cpm is the modified capability index, which is used when the process mean is not equal to the target value.

| Capability Index | Formula |

|---|---|

| Cp | (USL - LSL) / 6σ |

| Cpk | min[(USL - μ) / 3σ, (μ - LSL) / 3σ] |

| Cpm | min[(USL - μ) / 3σ, (μ - LSL) / 3σ] * (1 - (μ - T) / σ) |

Calculating Capability Index

To calculate the capability index, you need to follow these steps:

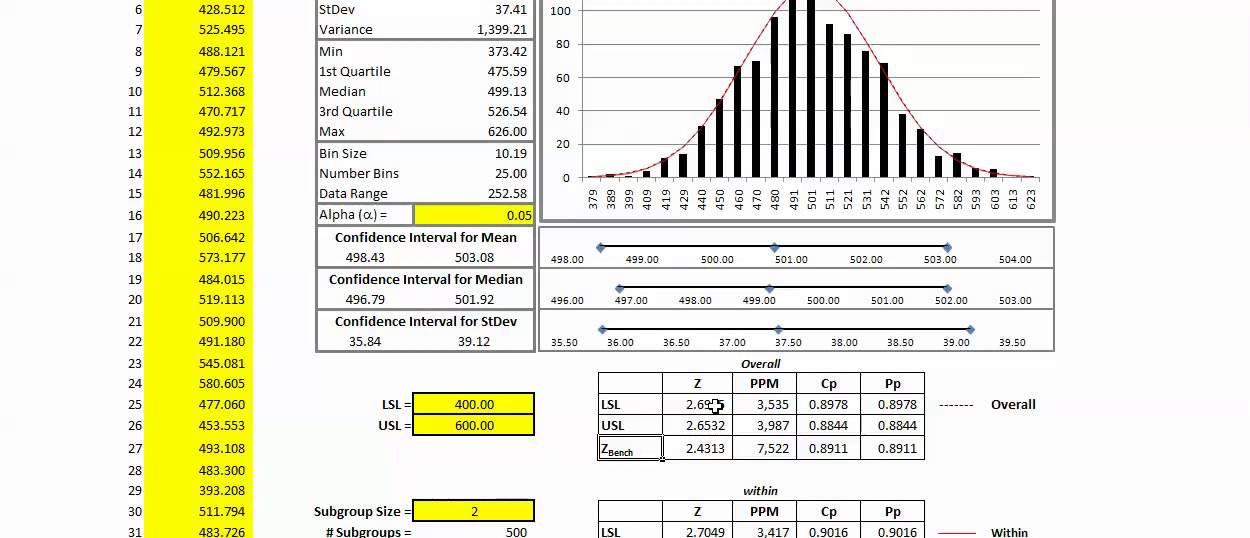

- Collect data: Collect a random sample of data from the process. The sample size should be sufficient to estimate the process mean and standard deviation accurately.

- Calculate the process mean: Calculate the mean of the sample data using the formula: μ = (Σx) / n, where x is the individual data point, and n is the sample size.

- Calculate the process standard deviation: Calculate the standard deviation of the sample data using the formula: σ = √[(Σ(x - μ)^2) / (n - 1)], where x is the individual data point, μ is the process mean, and n is the sample size.

- Specify the limits: Specify the upper and lower specification limits (USL and LSL) for the process.

- Calculate the capability index: Calculate the capability index using the formula: Cpk = min[(USL - μ) / 3σ, (μ - LSL) / 3σ].

Example Calculation

Suppose we have a process with a mean of 10 and a standard deviation of 1. The upper specification limit is 12, and the lower specification limit is 8. To calculate the capability index, we can use the following formula: Cpk = min[(12 - 10) / 3(1), (10 - 8) / 3(1)] = min[2 / 3, 2 / 3] = 0.67.

| Process Parameter | Value |

|---|---|

| Mean | 10 |

| Standard Deviation | 1 |

| Upper Specification Limit | 12 |

| Lower Specification Limit | 8 |

| Capability Index | 0.67 |

Interpretation of Capability Index

The capability index is a measure of the process’s ability to produce output within the specified limits. A high capability index value indicates that the process is capable of producing output within the specified limits, while a low value indicates that the process is not capable. The following table provides a general interpretation of the capability index:

| Capability Index | Interpretation |

|---|---|

| Less than 0.67 | Not capable |

| 0.67 to 1.00 | Marginally capable |

| 1.00 to 1.33 | Capable |

| 1.33 to 1.67 | Highly capable |

| Greater than 1.67 | World-class capable |

What is the purpose of calculating the capability index?

+The purpose of calculating the capability index is to determine the process’s ability to produce output within the specified limits. It is a measure of the process’s capability to meet customer requirements.

How is the capability index calculated?

+The capability index is calculated using the formula: Cpk = min[(USL - μ) / 3σ, (μ - LSL) / 3σ], where USL is the upper specification limit, LSL is the lower specification limit, μ is the process mean, and σ is the process standard deviation.

What is the interpretation of the capability index?

+The capability index is a measure of the process’s ability to produce output within the specified limits. A high capability index value indicates that the process is capable of producing output within the specified limits, while a low value indicates that the process is not capable.