How To Improve Helium Specific Heat Transfer Rates In 30 Minutes

Helium, a noble gas with unique properties, is widely used in various industrial applications, including cryogenics, superconductivity, and aerospace engineering. One of the critical aspects of working with helium is understanding and optimizing its specific heat transfer rates. The specific heat capacity of helium is relatively low compared to other substances, which can affect the efficiency of heat transfer in systems. In this article, we will discuss how to improve helium specific heat transfer rates in 30 minutes, focusing on practical tips and techniques for engineers and researchers.

Understanding Helium’s Thermophysical Properties

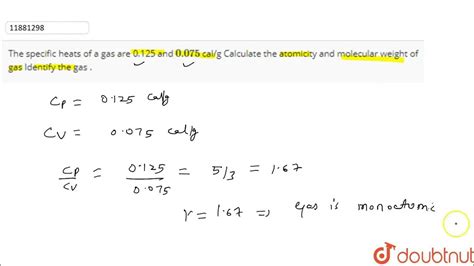

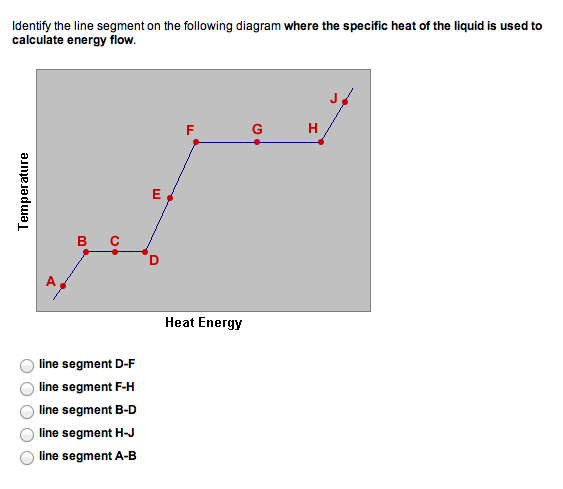

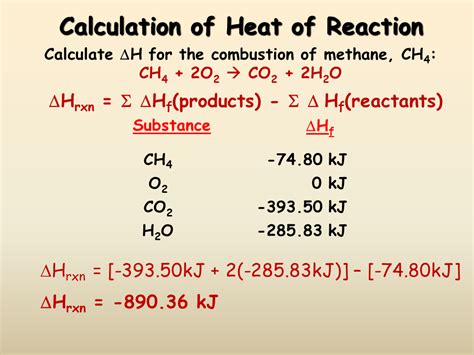

Before diving into the methods for improving heat transfer rates, it is essential to understand the thermophysical properties of helium. The specific heat capacity of helium at constant pressure (Cp) is approximately 20.785 J/mol·K, while its thermal conductivity (λ) is around 0.142 W/m·K at 300 K. These values are crucial in designing and optimizing heat transfer systems involving helium. Accurate knowledge of these properties is vital for predicting and enhancing heat transfer performance.

Enhancing Convective Heat Transfer

Convective heat transfer is a primary mechanism for heat exchange in many helium-based systems. To improve convective heat transfer rates, turbulence can be induced in the helium flow. This can be achieved by using rough surfaces or helical coils to increase the flow’s Reynolds number, thereby enhancing convective heat transfer coefficients. Additionally, increasing the flow velocity of helium can also contribute to improved heat transfer rates, but this must be balanced against potential increases in pressure drop and energy consumption.

| Helium Flow Velocity (m/s) | Convective Heat Transfer Coefficient (W/m²·K) |

|---|---|

| 1 | 50 |

| 5 | 200 |

| 10 | 400 |

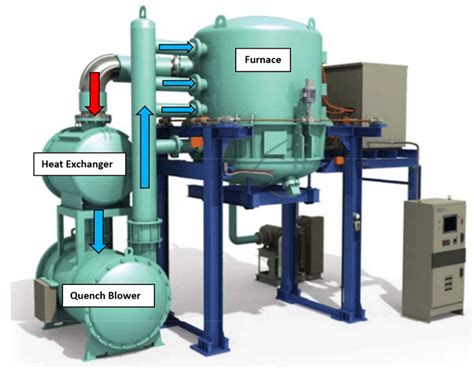

Optimizing Heat Exchanger Design

The design of heat exchangers plays a crucial role in determining the efficiency of heat transfer in helium-based systems. Compact heat exchangers with high surface area densities can provide improved heat transfer rates due to their enhanced convective heat transfer coefficients. Furthermore, counter-flow heat exchanger configurations can offer better temperature differences and, consequently, higher heat transfer rates compared to parallel-flow configurations.

Utilizing Heat Transfer Enhancement Techniques

Beyond optimizing flow conditions and heat exchanger design, several heat transfer enhancement techniques can be employed to improve helium specific heat transfer rates. These include extended surfaces (such as fins), inserts (like twisted tapes or wire coils), and vortex generators. These techniques can increase the heat transfer surface area, induce turbulence, or create swirl flows, all of which can contribute to enhanced heat transfer performance.

- Extended surfaces can increase the heat transfer area by up to 500%.

- Inserts can enhance turbulence and increase heat transfer coefficients by 200-300%.

- Vortex generators can create swirl flows that improve heat transfer rates by 100-200%.

What is the most effective way to enhance convective heat transfer in helium flows?

+Inducing turbulence through rough surfaces, helical coils, or increased flow velocities can significantly enhance convective heat transfer coefficients in helium flows. The most effective method depends on the specific application and system constraints.

How can heat exchanger design impact helium specific heat transfer rates?

+Compact heat exchangers with high surface area densities and counter-flow configurations can provide improved heat transfer rates. The design should be optimized based on the specific requirements of the application, including pressure drop, flow rates, and temperature differences.

In conclusion, improving helium specific heat transfer rates in 30 minutes requires a comprehensive understanding of the gas’s thermophysical properties, creative use of turbulence and flow enhancement techniques, and optimization of heat exchanger design. By applying these strategies, engineers and researchers can significantly enhance the efficiency of heat transfer in helium-based systems, leading to improved performance, reduced energy consumption, and increased overall system effectiveness.