How To Interpret Capability Index Formula Results For Business Decision Making?

The Capability Index formula, also known as the Capability Ratio or Cpk, is a statistical measure used to determine the ability of a process to produce output within specified limits. It is a crucial tool for business decision-making, as it helps organizations understand their processes' performance and identify areas for improvement. In this article, we will delve into the world of Capability Index formula results and provide a comprehensive guide on how to interpret them for informed business decision-making.

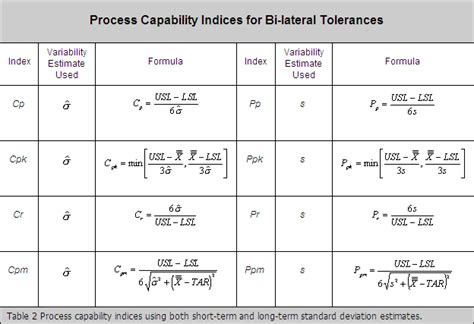

Understanding the Capability Index Formula

The Capability Index formula is calculated using the following formula: Cpk = min(Cpu, Cpl), where Cpu = (USL - μ) / 3σ and Cpl = (μ - LSL) / 3σ. Here, USL is the upper specification limit, LSL is the lower specification limit, μ is the process mean, and σ is the process standard deviation. The Cpk value ranges from 0 to 2, with higher values indicating better process capability.

Interpreting Capability Index Formula Results

To interpret the Capability Index formula results, businesses need to understand the different Cpk values and their implications. A Cpk value of:

- Less than 1 indicates that the process is not capable of producing output within the specified limits, and significant improvements are needed.

- Between 1 and 1.33 suggests that the process is capable, but there is room for improvement. In this case, businesses can implement minor adjustments to optimize the process.

- Between 1.33 and 1.67 indicates that the process is capable and relatively stable. However, ongoing monitoring and maintenance are necessary to ensure sustained performance.

- Greater than 1.67 suggests that the process is highly capable and robust. In this case, businesses can focus on maintaining the current level of performance and exploring opportunities for further improvement.

It is essential to note that the Capability Index formula results should be interpreted in the context of the specific business process and industry. For instance, a Cpk value of 1.5 may be acceptable in one industry, but it may not be sufficient in another industry where tighter tolerances are required.

| Cpk Value | Process Capability | Improvement Needed |

|---|---|---|

| Less than 1 | Not Capable | Significant |

| 1-1.33 | Capable | Minor Adjustments |

| 1.33-1.67 | Capable and Stable | Ongoing Monitoring |

| Greater than 1.67 | Highly Capable | Maintenance and Optimization |

Using Capability Index Formula Results for Business Decision-Making

The Capability Index formula results can be used to inform various business decisions, such as:

- Process optimization: By identifying areas for improvement, businesses can implement targeted changes to increase efficiency and reduce waste.

- Resource allocation: The Capability Index formula results can help businesses allocate resources more effectively, focusing on processes that require significant improvements.

- Supplier selection: When selecting suppliers, businesses can use the Capability Index formula results to evaluate the supplier’s process capability and ensure that it meets the required standards.

- Quality control: The Capability Index formula results can be used to monitor and control quality, ensuring that products or services meet the specified requirements.

In addition to these applications, the Capability Index formula results can also be used to identify opportunities for cost reduction, product development, and innovation. By leveraging these insights, businesses can drive growth, improve customer satisfaction, and gain a competitive edge in the market.

Case Study: Applying Capability Index Formula Results in the Manufacturing Industry

A manufacturing company producing automotive parts used the Capability Index formula to evaluate the capability of its production process. The results showed a Cpk value of 1.2, indicating that the process was capable but required minor adjustments. The company implemented changes to the production line, including operator training and equipment maintenance. As a result, the Cpk value increased to 1.5, and the company achieved significant improvements in quality and efficiency.

What is the primary purpose of the Capability Index formula?

+The primary purpose of the Capability Index formula is to determine the ability of a process to produce output within specified limits, enabling businesses to evaluate process capability and identify areas for improvement.

How can businesses use the Capability Index formula results to inform decision-making?

+Businesses can use the Capability Index formula results to inform decisions related to process optimization, resource allocation, supplier selection, quality control, and cost reduction, among others. By leveraging these insights, businesses can drive growth, improve customer satisfaction, and gain a competitive edge in the market.

In conclusion, the Capability Index formula results provide valuable insights into process capability, enabling businesses to make informed decisions and drive continuous improvement. By understanding the different Cpk values and their implications, businesses can optimize processes, allocate resources effectively, and improve quality control. As the manufacturing industry case study demonstrates, applying the Capability Index formula results can lead to significant improvements in quality, efficiency, and customer satisfaction.