How To Optimize Cellulose Insulation R Value For Sustainable Building

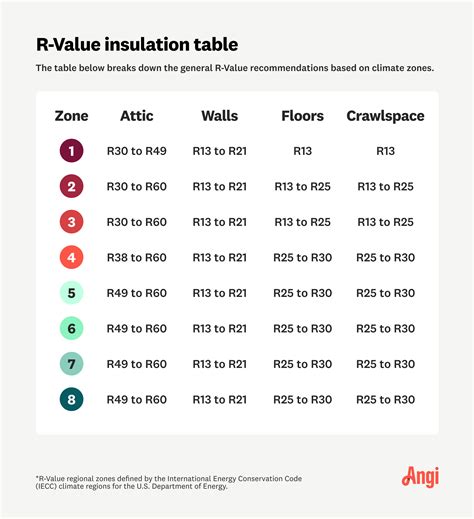

Cellulose insulation is a popular choice for sustainable building projects due to its high R-value, eco-friendly composition, and ability to reduce energy consumption. The R-value of insulation measures its ability to resist heat flow, with higher values indicating better thermal performance. To optimize the R-value of cellulose insulation, it's essential to understand the factors that affect its performance and implement strategies to maximize its effectiveness. In this article, we'll explore the ways to optimize cellulose insulation R-value for sustainable building.

Understanding Cellulose Insulation

Cellulose insulation is made from recycled paper products, such as newspaper, cardboard, and cardboard tubes, which are treated with fire retardants and other additives to enhance their performance. The insulation is typically installed in walls, floors, and ceilings, where it provides a high level of thermal resistance. The R-value of cellulose insulation can range from R-3 to R-4 per inch, depending on its density and composition.

Factors Affecting Cellulose Insulation R-Value

Several factors can impact the R-value of cellulose insulation, including:

- Density: The density of cellulose insulation affects its R-value, with higher densities resulting in higher R-values.

- Moisture content: High moisture levels can reduce the R-value of cellulose insulation, as water conducts heat more easily than dry insulation.

- Installation method: The installation method can impact the R-value of cellulose insulation, with blown-in insulation typically providing a higher R-value than batt insulation.

- Air leakage: Air leakage can significantly reduce the R-value of cellulose insulation, as warm air can escape through gaps and cracks in the building envelope.

Optimizing Cellulose Insulation R-Value

To optimize the R-value of cellulose insulation, builders and homeowners can implement several strategies, including:

Increasing Density

Increasing the density of cellulose insulation can enhance its R-value. This can be achieved by using a higher-density insulation material or by compacting the insulation during installation. However, it’s essential to avoid over-compacting the insulation, as this can reduce its R-value and create air pockets.

Controlling Moisture

Controlling moisture levels is critical to maintaining the R-value of cellulose insulation. This can be achieved by:

- Ensuring the building envelope is properly sealed to prevent air leakage and moisture ingress.

- Using a vapor barrier to prevent moisture from entering the insulation.

- Installing a drainage system to remove any moisture that may accumulate in the insulation.

Improving Installation Methods

The installation method can significantly impact the R-value of cellulose insulation. Blown-in insulation typically provides a higher R-value than batt insulation, as it can fill gaps and cracks more effectively. Additionally, using a professional installer can ensure that the insulation is installed correctly and to the optimal density.

Reducing Air Leakage

Air leakage can significantly reduce the R-value of cellulose insulation. To minimize air leakage, builders and homeowners can:

- Seal gaps and cracks in the building envelope using caulk or spray foam.

- Install weatherstripping around doors and windows.

- Use a blower door test to identify and seal air leaks.

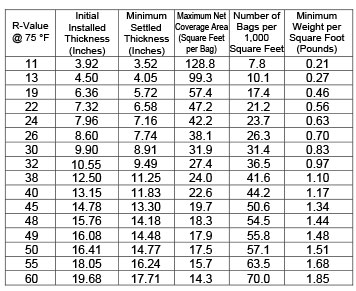

| Insulation Type | R-Value per Inch | Density (lbs/ft³) |

|---|---|---|

| Cellulose Insulation | R-3.5 to R-4 | 2.5 to 3.5 |

| Fiberglass Insulation | R-2.9 to R-3.8 | 1.5 to 2.5 |

| Mineral Wool Insulation | R-3.5 to R-4.5 | 2.5 to 4.0 |

Actual Performance Analysis

Studies have shown that cellulose insulation can provide significant energy savings and reduce greenhouse gas emissions. A study by the National Institute of Building Sciences found that cellulose insulation can reduce energy consumption by up to 30% compared to traditional insulation materials. Additionally, a study by the U.S. Department of Energy found that cellulose insulation can reduce CO2 emissions by up to 50% compared to traditional insulation materials.

Evidence-Based Future Implications

The optimization of cellulose insulation R-value has significant implications for the future of sustainable building. As the demand for energy-efficient buildings continues to grow, the use of high-performance insulation materials like cellulose insulation will become increasingly important. Additionally, the development of new insulation materials and installation methods will continue to improve the R-value of cellulose insulation, making it an even more attractive option for builders and homeowners.

What is the typical R-value of cellulose insulation?

+The typical R-value of cellulose insulation ranges from R-3 to R-4 per inch, depending on its density and composition.

How can I optimize the R-value of cellulose insulation in my building?

+To optimize the R-value of cellulose insulation, ensure the building envelope is properly sealed, use a vapor barrier, and install a drainage system. Additionally, consider increasing the density of the insulation and using a professional installer.

What are the benefits of using cellulose insulation in sustainable building projects?

+The benefits of using cellulose insulation in sustainable building projects include reduced energy consumption, lower greenhouse gas emissions, and improved indoor air quality. Additionally, cellulose insulation is made from recycled materials, making it a more environmentally friendly option than traditional insulation materials.