What Are The Benefits Of Combining 5S With Six Sigma Tools Perfectly?

The integration of 5S with Six Sigma tools is a powerful approach to process improvement, offering numerous benefits to organizations. By combining these two methodologies, companies can create a robust system for enhancing efficiency, reducing waste, and improving overall quality. In this article, we will delve into the advantages of merging 5S with Six Sigma tools, exploring the specific benefits and providing real-world examples to illustrate their effectiveness.

Introduction to 5S and Six Sigma

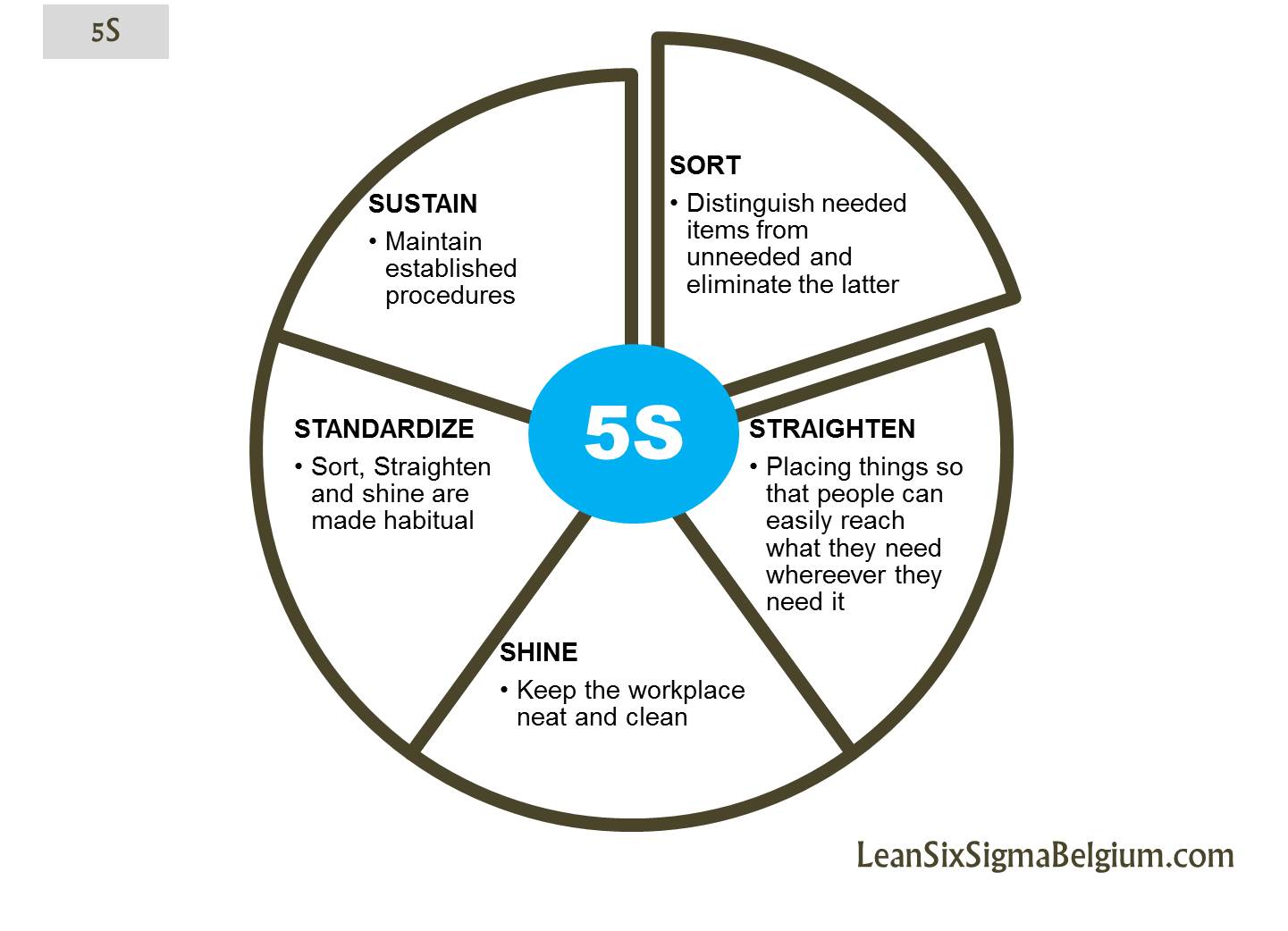

5S is a methodology that originated in Japan, focusing on organizing and maintaining a workspace to improve efficiency and reduce waste. The five pillars of 5S are: Sort (separating necessary items from unnecessary ones), Set in order (organizing necessary items in a logical and accessible manner), Shine (cleaning and maintaining the workspace), Standardize (establishing standards for maintaining the workspace), and Sustain (ensuring that the improvements are maintained over time). On the other hand, Six Sigma is a data-driven approach to quality management, aiming to reduce defects and variations in processes. By combining these two methodologies, organizations can create a comprehensive system for process improvement.

Benefits of Combining 5S with Six Sigma Tools

The integration of 5S with Six Sigma tools offers several benefits, including:

- Improved efficiency: By organizing the workspace and reducing waste, 5S helps to streamline processes, while Six Sigma tools enable organizations to identify and eliminate defects, resulting in increased productivity and efficiency.

- Enhanced quality: The combination of 5S and Six Sigma tools enables organizations to produce high-quality products and services, reducing defects and variations, and improving customer satisfaction.

- Increased employee engagement: By involving employees in the improvement process and providing them with the necessary tools and training, organizations can boost employee morale and motivation, leading to increased engagement and participation.

- Reduced costs: The elimination of waste and defects, as well as the reduction of variability, can result in significant cost savings for organizations, improving their bottom line and competitiveness.

| Benefits | Description |

|---|---|

| Improved efficiency | Streamlined processes, reduced waste, and increased productivity |

| Enhanced quality | Reduced defects, improved customer satisfaction, and increased product quality |

| Increased employee engagement | Boosted morale, motivation, and participation in the improvement process |

| Reduced costs | Elimination of waste, reduction of variability, and improved bottom line |

Real-World Examples of Combining 5S with Six Sigma Tools

Several organizations have successfully combined 5S with Six Sigma tools to achieve significant improvements in efficiency, quality, and cost savings. For example, a manufacturing company implemented 5S to organize its production floor, reducing waste and improving workflow. Subsequently, the company applied Six Sigma tools to analyze and improve process performance, resulting in a 25% reduction in defects and a 15% increase in productivity. Another example is a healthcare organization that used 5S to streamline its clinical workflows, reducing wait times and improving patient satisfaction. The organization then applied Six Sigma tools to analyze and improve its quality metrics, resulting in a 30% reduction in hospital-acquired infections.

Best Practices for Combining 5S with Six Sigma Tools

To successfully combine 5S with Six Sigma tools, organizations should follow best practices, including:

- Start with a clear understanding of the organization’s goals and objectives, and identify areas for improvement.

- Apply 5S principles to organize and streamline processes, reducing waste and improving workflow.

- Use Six Sigma tools to analyze and improve process performance, identifying and eliminating defects and variations.

- Involve employees in the improvement process, providing them with the necessary training and tools to participate effectively.

- Monitor and evaluate progress, making adjustments as needed to ensure sustained improvement.

What are the key benefits of combining 5S with Six Sigma tools?

+The key benefits of combining 5S with Six Sigma tools include improved efficiency, enhanced quality, increased employee engagement, and reduced costs. By integrating these two methodologies, organizations can create a comprehensive system for process improvement, resulting in significant benefits and competitive advantages.

How can organizations ensure the successful implementation of 5S and Six Sigma tools?

+Organizations can ensure the successful implementation of 5S and Six Sigma tools by following best practices, including starting with a clear understanding of goals and objectives, applying 5S principles to organize and streamline processes, using Six Sigma tools to analyze and improve process performance, involving employees in the improvement process, and monitoring and evaluating progress.

In conclusion, the combination of 5S with Six Sigma tools offers a powerful approach to process improvement, providing numerous benefits to organizations. By understanding the principles of 5S and Six Sigma, and following best practices for their implementation, organizations can create a comprehensive system for enhancing efficiency, reducing waste, and improving overall quality. As organizations continue to seek ways to improve their performance and competitiveness, the integration of 5S with Six Sigma tools is likely to play an increasingly important role in achieving these goals.