What Are The Uses Of Specific Heat Of Magnesium In Industry 2025?

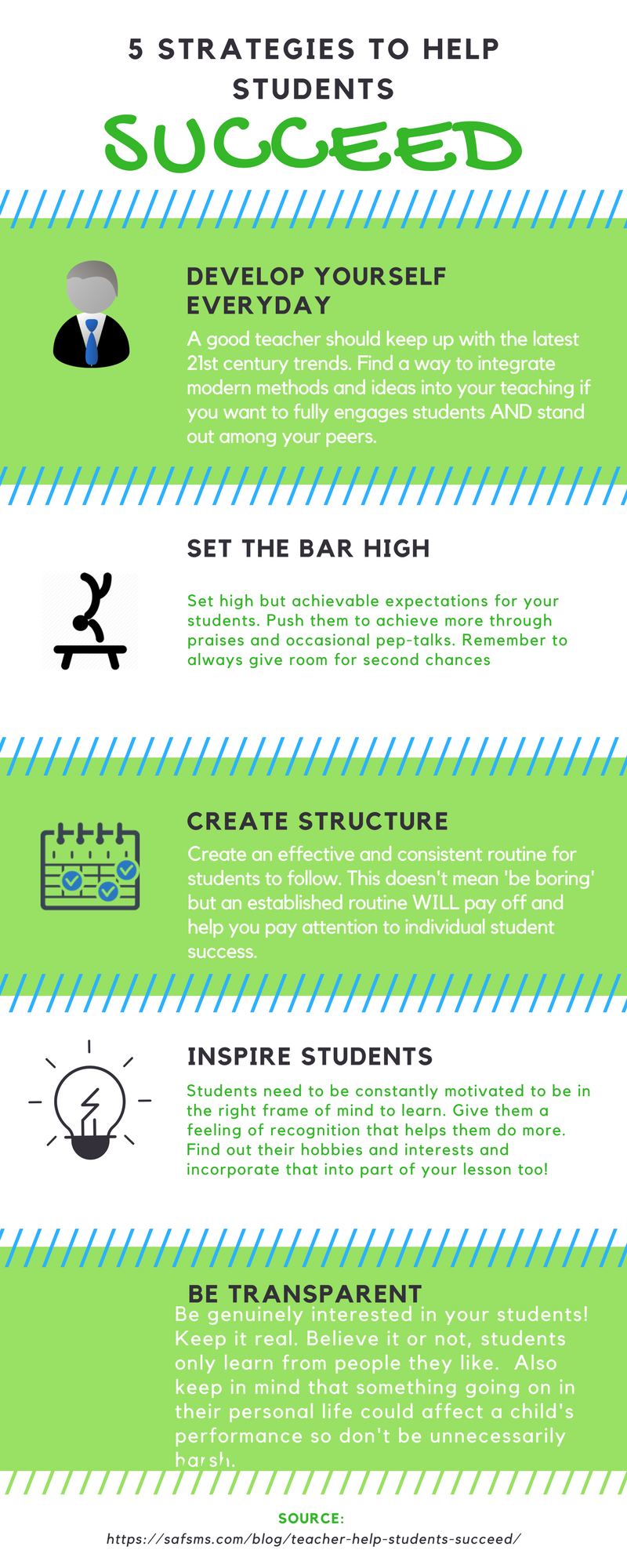

The specific heat of magnesium, denoted as the amount of heat per unit mass required to raise the temperature of magnesium by one degree Celsius, is a critical property that finds numerous applications in various industries. With a specific heat capacity of approximately 1.02 kJ/kg·K, magnesium's unique thermal properties make it an essential material in several sectors. As of 2025, the uses of specific heat of magnesium in industry are diverse and continue to expand due to advancements in technology and the increasing demand for lightweight, high-performance materials.

Applications of Magnesium’s Specific Heat in Industry

Magnesium’s specific heat plays a vital role in its application across different industries, including aerospace, automotive, electronics, and construction. The ability of magnesium to absorb and release heat efficiently makes it an ideal material for various industrial processes and products. Some of the key applications of magnesium’s specific heat in industry include:

Aerospace and Defense

In the aerospace and defense sectors, magnesium alloys are used extensively due to their high strength-to-weight ratio, corrosion resistance, and excellent thermal properties. The specific heat of magnesium is crucial in the design and development of aircraft and missile components, where heat management is critical for performance and safety. For instance, magnesium is used in the production of engine components, gearboxes, and other structural parts that require efficient heat dissipation.

| Application | Specific Heat Requirement |

|---|---|

| Aircraft Engine Components | High specific heat for efficient heat absorption and dissipation |

| Missile Components | Optimized specific heat for controlled thermal expansion and contraction |

Automotive Industry

In the automotive sector, magnesium alloys are increasingly used for producing vehicle components such as gearboxes, engine blocks, and wheels. The specific heat of magnesium helps in reducing the overall weight of vehicles, thereby improving fuel efficiency and reducing emissions. Moreover, magnesium’s high thermal conductivity and specific heat capacity enable efficient heat management in engine components, contributing to improved engine performance and longevity.

- Engine blocks and cylinder heads: Magnesium's specific heat helps in efficient heat dissipation, reducing the risk of overheating and improving engine durability.

- Transmission components: The high specific heat of magnesium ensures smooth gear shifting and reduces the risk of thermal damage to transmission components.

Electronics and Consumer Goods

Magnesium’s specific heat is also utilized in the production of electronic devices and consumer goods. For example, magnesium is used in the manufacture of laptop casings, smartphone components, and other portable electronic devices due to its lightweight, corrosion-resistant, and heat-dissipating properties. The specific heat of magnesium helps in maintaining the optimal operating temperature of electronic components, thereby enhancing their performance and lifespan.

In addition to its applications in high-tech industries, magnesium's specific heat is also valuable in more traditional sectors such as construction and packaging. In construction, magnesium-based materials are used for producing lightweight, fire-resistant panels and roofing materials. The specific heat of magnesium contributes to the fire-resistant properties of these materials by slowing down the spread of heat and flames.

Future Implications and Research Directions

As research and development continue to advance, new applications of magnesium’s specific heat are emerging. For instance, magnesium is being explored as a potential material for thermal energy storage systems due to its high specific heat capacity and thermal conductivity. Such systems could play a crucial role in enhancing the efficiency of renewable energy sources and reducing energy consumption in buildings and industries.

| Emerging Application | Specific Heat Requirement |

|---|---|

| Thermal Energy Storage Systems | High specific heat for efficient thermal energy absorption and release |

| Advanced Aerospace Materials | Optimized specific heat for improved thermal management in extreme environments |

What are the primary factors influencing the specific heat of magnesium?

+The primary factors influencing the specific heat of magnesium include its alloy composition, crystal structure, and the presence of impurities. The specific heat can vary slightly depending on the magnesium alloy and its manufacturing process.

How does the specific heat of magnesium compare to other common metals?

+Magnesium has a relatively high specific heat capacity compared to other common metals. For example, the specific heat of aluminum is approximately 0.90 kJ/kg·K, while that of steel is around 0.50 kJ/kg·K. Magnesium's high specific heat makes it particularly useful for applications requiring efficient heat management.

In conclusion, the specific heat of magnesium plays a vital role in its diverse applications across various industries. As technology continues to evolve and the demand for high-performance, lightweight materials increases, the importance of magnesium’s specific heat will only continue to grow. Research into new applications and the development of advanced magnesium alloys will further expand the potential uses of this versatile metal, contributing to innovations in fields such as aerospace, automotive, electronics, and beyond.