When To Review And Update Process Capability Index Calculation Procedures 2025

The process capability index (Cp, Cpk) is a statistical measure used to assess the ability of a process to produce output within specified limits. It is a crucial metric in Six Sigma and other quality management methodologies, as it provides insight into the process's potential to meet customer requirements. As of 2025, it is essential to review and update process capability index calculation procedures to ensure they remain relevant and effective in today's fast-paced manufacturing environment.

Introduction to Process Capability Index

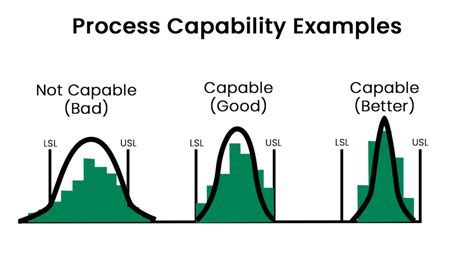

The process capability index is calculated using the following formula: Cp = (USL - LSL) / 6σ, where USL is the upper specification limit, LSL is the lower specification limit, and σ is the standard deviation of the process. Cpk is a more comprehensive metric that takes into account the process mean (μ) and is calculated as Cpk = min[(USL - μ) / 3σ, (μ - LSL) / 3σ]. These metrics provide a snapshot of the process’s ability to produce output within specified limits, but they require regular review and updating to ensure their continued effectiveness.

Reasons to Review and Update Process Capability Index Calculation Procedures

There are several reasons to review and update process capability index calculation procedures in 2025. Changing customer requirements and advances in technology are driving the need for more accurate and reliable process capability metrics. Additionally, quality management systems such as ISO 9001 require regular review and updating of quality metrics, including process capability indices. The following table summarizes the key reasons to review and update process capability index calculation procedures:

| Reason | Description |

|---|---|

| Changing customer requirements | Customer requirements and specifications may change over time, requiring updates to process capability index calculations |

| Advances in technology | New technologies and manufacturing processes may require updated process capability index calculations to ensure accuracy and reliability |

| Quality management system requirements | Quality management systems such as ISO 9001 require regular review and updating of quality metrics, including process capability indices |

Steps to Review and Update Process Capability Index Calculation Procedures

To review and update process capability index calculation procedures, organizations should follow a structured approach. The following steps provide a general framework for reviewing and updating process capability index calculation procedures:

- Review current process capability index calculations: Review current process capability index calculations to identify areas for improvement and potential updates

- Gather relevant data: Gather relevant data on process performance, including specification limits, process mean, and standard deviation

- Update process capability index calculations: Update process capability index calculations using the latest data and methodologies

- Verify and validate results: Verify and validate the updated process capability index calculations to ensure accuracy and reliability

- Document and communicate changes: Document and communicate changes to process capability index calculation procedures to relevant stakeholders

Best Practices for Reviewing and Updating Process Capability Index Calculation Procedures

When reviewing and updating process capability index calculation procedures, organizations should follow best practices to ensure that their quality metrics remain accurate and reliable. The following best practices provide guidance on reviewing and updating process capability index calculation procedures:

- Use a structured approach: Use a structured approach to review and update process capability index calculation procedures to ensure consistency and accuracy

- Involve relevant stakeholders: Involve relevant stakeholders, including quality engineers, manufacturing engineers, and customer representatives, in the review and update process

- Use the latest methodologies and technologies: Use the latest methodologies and technologies, such as statistical process control and machine learning, to update process capability index calculations

What is the purpose of reviewing and updating process capability index calculation procedures?

+The purpose of reviewing and updating process capability index calculation procedures is to ensure that quality metrics remain accurate and reliable, and that organizations are able to meet changing customer requirements and advances in technology.

How often should process capability index calculation procedures be reviewed and updated?

+Process capability index calculation procedures should be reviewed and updated regularly, ideally as part of a continuous improvement program, to ensure that they remain effective and relevant.

In conclusion, reviewing and updating process capability index calculation procedures is essential to ensure that quality metrics remain accurate and reliable. By following a structured approach and using the latest methodologies and technologies, organizations can ensure that their process capability index calculations remain effective and relevant in today’s fast-paced manufacturing environment.