When Will Capability Index Formula Be Updated For New Industry Standards 2025?

The Capability Index formula, a widely used statistical measure to evaluate the capability of a process, has been a cornerstone in quality control and manufacturing for decades. As industries evolve and new standards emerge, there is a growing anticipation regarding the update of the Capability Index formula to align with the new industry standards of 2025. The current formula, which calculates the capability of a process based on its performance relative to its specifications, has undergone several revisions since its inception. However, with the rapid advancement in technology and the increasing demand for precision and efficiency, the need for an updated formula that incorporates modern statistical methods and addresses contemporary challenges has become more pressing than ever.

Background and Current Status of the Capability Index Formula

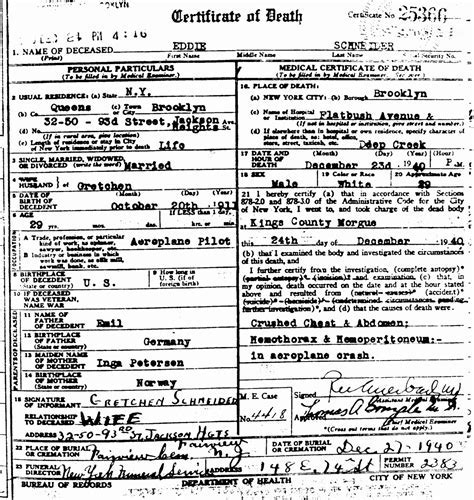

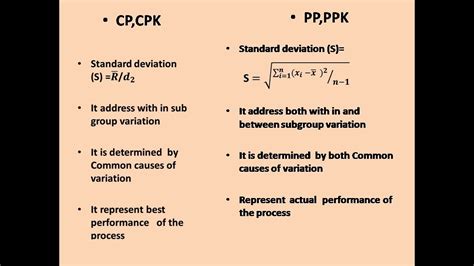

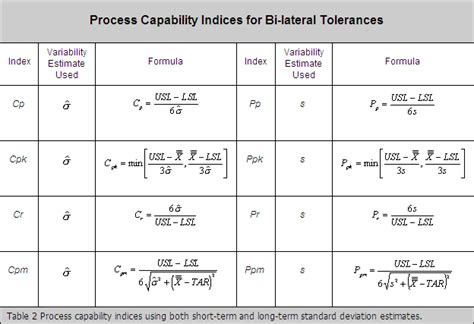

The Capability Index, often denoted as Cpk, is a statistical tool used to measure the ability of a process to produce output within specified limits. It takes into account both the centering of the process and its variability. The formula for Cpk is given by:

Cpk = min(Cpu, Cpl)

where Cpu = (USL - μ) / (3σ) and Cpl = (μ - LSL) / (3σ), USL is the upper specification limit, LSL is the lower specification limit, μ is the process mean, and σ is the standard deviation of the process. This formula has been instrumental in helping manufacturers and quality control specialists assess process capability and make informed decisions about process improvements.

New Industry Standards and the Need for an Update

As we approach 2025, new industry standards are being introduced that emphasize not only the traditional aspects of quality and reliability but also sustainability, digitalization, and customer-centricity. The updated standards, such as those related to Industry 4.0 and the integration of artificial intelligence (AI) and the Internet of Things (IoT) in manufacturing, require more sophisticated and dynamic metrics for process evaluation. The current Capability Index formula, while effective for its original purpose, may not fully capture the complexities and nuances of modern manufacturing processes.

Key areas where the Capability Index formula might need revision include real-time data analysis, predictive maintenance, and adaptability to changing production conditions. Incorporating these aspects into the formula would enable manufacturers to better assess their processes in the context of smart manufacturing and make data-driven decisions to improve efficiency, reduce waste, and enhance product quality.

| Current Capability Index Formula Limitations | Potential Updates for 2025 Standards |

|---|---|

| Lack of Real-Time Data Integration | Incorporation of IoT and AI for Real-Time Analysis |

| Static Nature of the Formula | Dynamic Formula Adjusting to Production Conditions |

| Focus on Traditional Quality Metrics | Inclusion of Sustainability and Customer Satisfaction Metrics |

Expected Timeline and Implementation Challenges

The exact timeline for updating the Capability Index formula to meet the new industry standards of 2025 is subject to the deliberations and agreements among industry stakeholders, standardization bodies, and regulatory agencies. Given the complexity of the task and the need for international coordination, it is likely that the process will be gradual, with preliminary discussions and drafts emerging in the near future, followed by a phased implementation.

Implementation challenges will include ensuring that the updated formula is backward compatible to some extent, to allow for a smooth transition from the current standards, and providing adequate training and support for professionals who will be using the new formula. Moreover, there will be a need for case studies and benchmarking to demonstrate the efficacy and applicability of the updated formula across different industries and manufacturing scenarios.

Future Implications and Opportunities

The update of the Capability Index formula to align with the 2025 industry standards presents not only challenges but also significant opportunities for innovation and growth. By embracing modern statistical methods, digital technologies, and a more holistic approach to process capability, manufacturers can expect to achieve higher levels of efficiency, quality, and customer satisfaction. This, in turn, can lead to competitive advantages, market growth, and enhanced brand reputation.

Furthermore, an updated Capability Index formula can facilitate cross-industry learning and collaboration, as companies from different sectors share best practices and innovative solutions for process improvement. This could pave the way for the development of new business models and revenue streams, particularly in the areas of consulting, training, and technology services related to process capability assessment and improvement.

What are the primary drivers for updating the Capability Index formula?

+The primary drivers include the adoption of Industry 4.0 technologies, the need for more dynamic and real-time process evaluation, and the integration of sustainability and customer-centric metrics into quality control.

How might the updated Capability Index formula impact manufacturing processes?

+The updated formula could lead to more efficient processes, improved product quality, reduced waste, and enhanced customer satisfaction, by providing a more comprehensive and dynamic assessment of process capability.

In conclusion, the update of the Capability Index formula to meet the new industry standards of 2025 is a significant development that holds the potential to transform the way manufacturers evaluate and improve their processes. While the exact timeline and details of the update are still in the process of being defined, it is clear that this change will have far-reaching implications for the manufacturing sector, offering opportunities for innovation, growth, and enhanced competitiveness in a rapidly evolving global market.