Where Can I Find Capability Index Formula For Lean Manufacturing Implementation?

The Capability Index, also known as the Process Capability Index (Cp, Cpk), is a statistical measure used to assess the ability of a process to produce output within specified limits. In the context of Lean manufacturing, understanding and applying the Capability Index formula is crucial for evaluating and improving process performance. To find the Capability Index formula for Lean manufacturing implementation, you can refer to various resources, including quality management standards, Lean manufacturing literature, and online calculators.

Introduction to Capability Index Formula

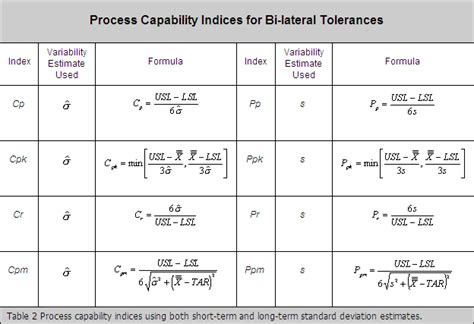

The Capability Index formula is used to calculate the Cp and Cpk values, which indicate the spread of the process data relative to the specification limits. The Cp formula is calculated as follows: Cp = (USL - LSL) / 6σ, where USL is the Upper Specification Limit, LSL is the Lower Specification Limit, and σ is the standard deviation of the process. The Cpk formula is calculated as: Cpk = min(CpL, CpU), where CpL = (USL - μ) / 3σ and CpU = (μ - LSL) / 3σ, and μ is the mean of the process.

Calculating Capability Index

To calculate the Capability Index, you need to follow these steps:

- Collect a sufficient amount of data from the process, typically 20-30 subgroups.

- Calculate the mean (μ) and standard deviation (σ) of the process data.

- Determine the Upper Specification Limit (USL) and Lower Specification Limit (LSL) for the process.

- Calculate the Cp and Cpk values using the formulas mentioned above.

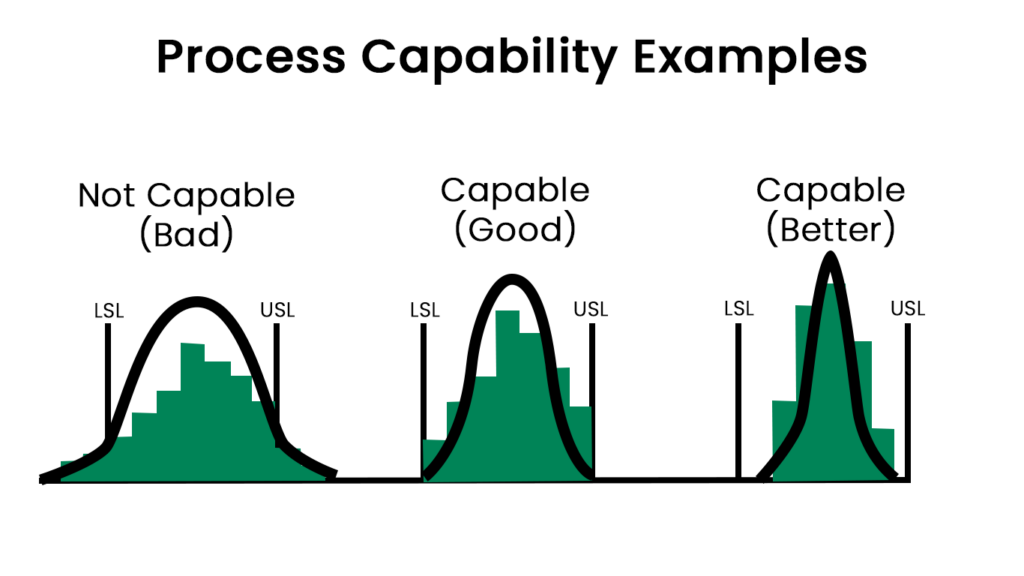

| Capability Index | Interpretation |

|---|---|

| Cp < 1 | The process is not capable of meeting the specifications. |

| 1 ≤ Cp < 1.33 | The process is barely capable of meeting the specifications. |

| 1.33 ≤ Cp < 1.67 | The process is capable of meeting the specifications, but with some variation. |

| Cp ≥ 1.67 | The process is fully capable of meeting the specifications. |

Applying Capability Index in Lean Manufacturing

In Lean manufacturing, the Capability Index is used to identify opportunities for process improvement and to monitor the effectiveness of improvement initiatives. By applying the Capability Index formula, manufacturers can:

- Evaluate process performance and identify areas for improvement.

- Set realistic targets for process improvement initiatives.

- Monitor the progress of improvement initiatives and adjust strategies as needed.

Case Study: Implementing Capability Index in a Manufacturing Process

A manufacturing company producing precision parts implemented the Capability Index formula to evaluate the performance of their machining process. By collecting data and calculating the Cp and Cpk values, they determined that their process was barely capable of meeting the specifications (Cp = 1.1). The company then launched a series of improvement initiatives, including operator training and equipment maintenance, which resulted in a significant reduction in process variation and an increase in the Cp value (Cp = 1.5). The company was able to improve product quality and reduce waste, leading to cost savings and increased customer satisfaction.

What is the difference between Cp and Cpk?

+Cp and Cpk are both measures of process capability, but they differ in how they account for the process mean. Cp is a measure of the spread of the process data relative to the specification limits, while Cpk takes into account the location of the process mean relative to the specification limits. Cpk is a more comprehensive measure of process capability, as it considers both the spread and the centering of the process.

How do I determine the sample size for calculating the Capability Index?

+The sample size for calculating the Capability Index depends on the desired level of precision and the variability of the process. A general rule of thumb is to collect at least 20-30 subgroups, with each subgroup consisting of 5-10 individual measurements. However, the sample size may need to be adjusted based on the specific process and the desired level of precision.

In conclusion, the Capability Index formula is a powerful tool for evaluating and improving process performance in Lean manufacturing. By understanding and applying the formula, manufacturers can identify opportunities for improvement, set realistic targets, and monitor the effectiveness of improvement initiatives. With its ability to provide a comprehensive measure of process capability, the Capability Index is an essential metric for any Lean manufacturing implementation.