Where Does The Capability Index Formula Fit In The Quality Management Framework?

The Capability Index formula is a crucial component in the Quality Management framework, specifically within the realm of Statistical Process Control (SPC) and Continuous Improvement. It is used to assess the ability of a process to produce output within specified limits, thereby measuring its capability. The formula is vital for understanding how well a process is performing in relation to its specifications and for identifying areas that require improvement.

Introduction to Capability Index

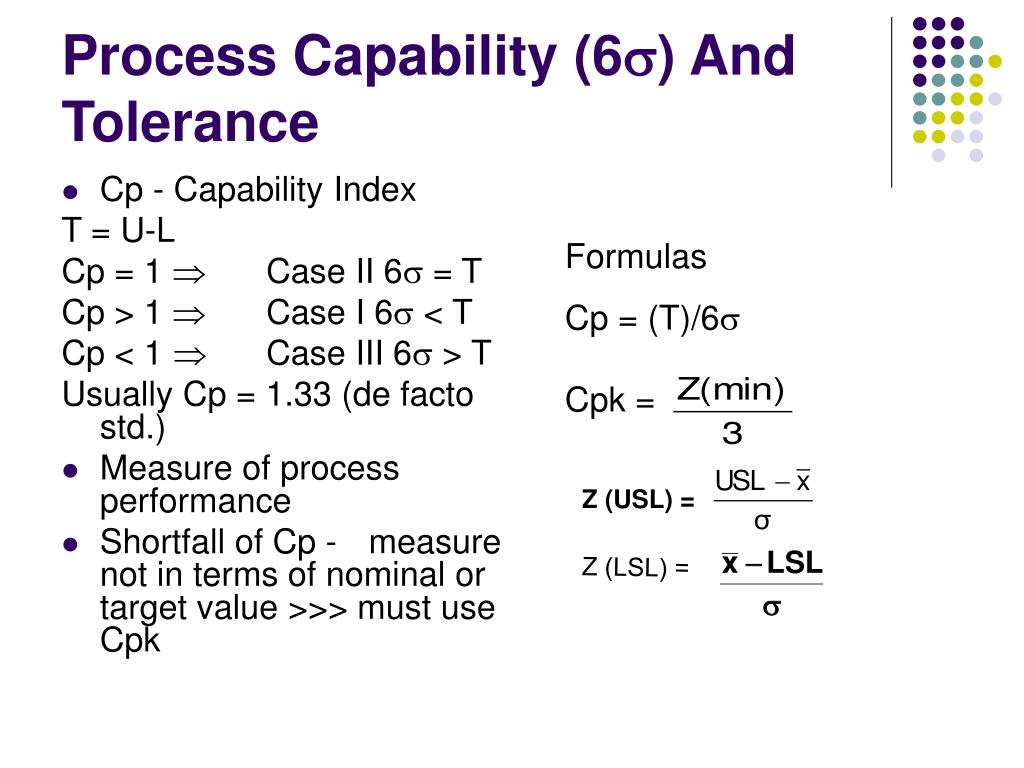

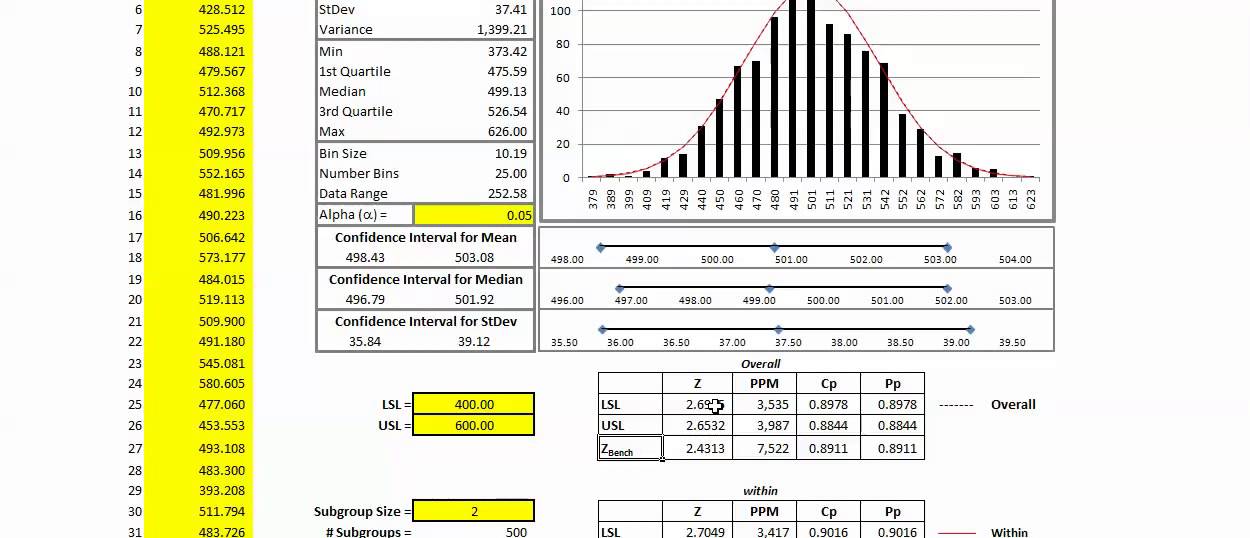

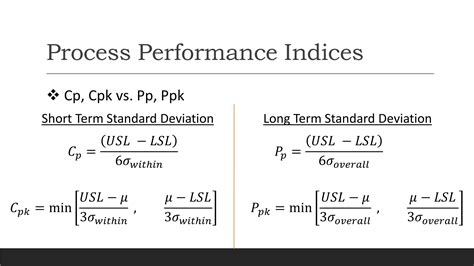

The Capability Index, often denoted as Cpk, is a statistical measure that compares the width of the specification limits to the width of the process distribution. It provides a quantitative measure of the process’s ability to produce output that meets the specified requirements. A higher Cpk value indicates a more capable process, meaning it is better at producing output within the desired specifications. The formula for Cpk is given by: Cpk = min(Cpu, Cpl), where Cpu = (USL - μ) / (3σ) and Cpl = (μ - LSL) / (3σ), with USL being the upper specification limit, LSL the lower specification limit, μ the process mean, and σ the process standard deviation.

Understanding the Components of the Capability Index Formula

Process Mean (μ) and Process Standard Deviation (σ) are critical components in calculating the Capability Index. The process mean represents the average value of the process output, while the process standard deviation measures the variability or spread of the output. The specification limits, USL and LSL, are determined based on the requirements of the product or service being produced. The relationship between these components and the capability index is fundamental in determining the process’s capability.

| Capability Index Value | Process Capability |

|---|---|

| Cpk < 1 | Not capable |

| Cpk = 1 | Capable |

| Cpk > 1 | More than capable |

Role in Quality Management Framework

The Capability Index formula plays a pivotal role in the Quality Management framework by facilitating the identification of opportunities for process improvement. It is integral to the Plan-Do-Check-Act (PDCA) cycle, a core element of quality management systems such as ISO 9001. During the “Check” phase, the Capability Index is used to assess the process’s performance against its specifications. If the process is found to be not capable (Cpk < 1), actions are planned and implemented during the “Act” phase to improve the process, which could involve reducing variability, adjusting the process mean, or revising the specification limits.

Implementation and Continuous Improvement

The implementation of the Capability Index formula involves data collection from the process, calculation of the Cpk value, and interpretation of the results. Continuous improvement is facilitated through the iterative application of the PDCA cycle, where process adjustments are made based on the Capability Index analysis, and the process is continually monitored and evaluated to ensure that it remains capable over time.

- Regular Monitoring: Continuous monitoring of the process to ensure that it remains within the specified limits.

- Corrective Actions: Implementation of corrective actions when the process deviates from its capable state.

- Process Optimization: Ongoing efforts to optimize the process, reducing variability and improving its capability.

What does a Cpk value of 1.33 indicate about a process?

+A Cpk value of 1.33 indicates that the process is capable, with a margin that suggests it is centered and has minimal variability compared to its specification limits. This is often considered a benchmark for processes that are well-controlled and capable of producing high-quality output.

How is the Capability Index used in Six Sigma initiatives?

+The Capability Index is a critical tool in Six Sigma initiatives, used to measure the capability of processes before and after improvement projects. It helps in setting baseline performance, identifying opportunities for improvement, and measuring the success of projects aimed at reducing defects and variability.

In conclusion, the Capability Index formula is a fundamental tool in the Quality Management framework, enabling organizations to assess and improve process capability. Its application is widespread across various industries, facilitating continuous improvement and the achievement of high-quality standards. By understanding and effectively utilizing the Capability Index, organizations can enhance their competitiveness and customer satisfaction through the production of high-quality products and services.