Why Is Process Capability Index Calculation Important For Quality Engineers 2025

Process capability index calculation is a crucial aspect of quality engineering, particularly in the manufacturing sector. As we move into 2025, the importance of this calculation will only continue to grow, driven by the increasing demand for high-quality products and the need for efficient production processes. In this context, understanding the process capability index calculation is essential for quality engineers to ensure that their processes are operating within specified limits and producing products that meet customer requirements.

Introduction to Process Capability Index

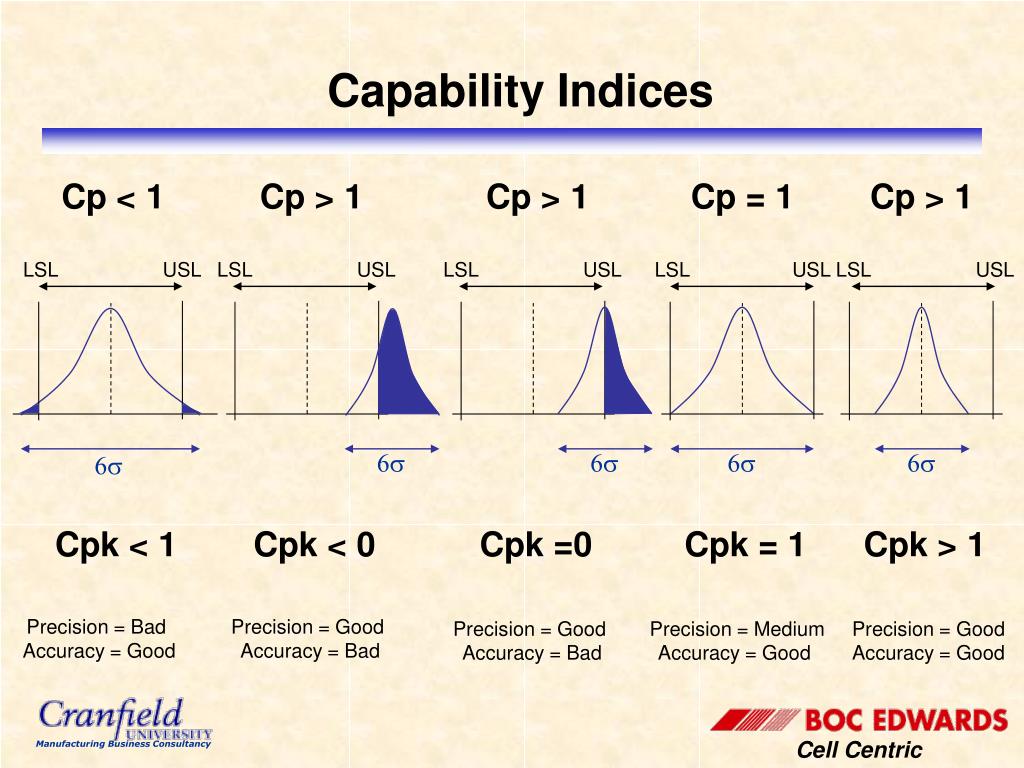

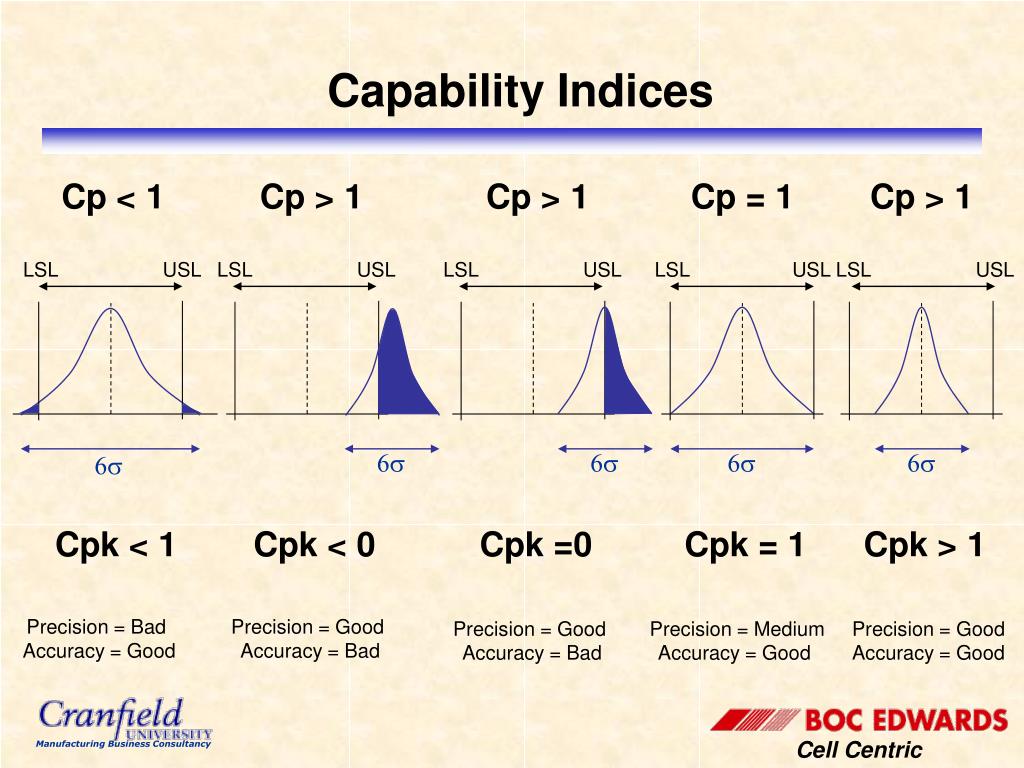

The process capability index is a statistical measure that compares the variability of a process to its specifications. It provides a snapshot of the process’s ability to produce products within the desired specifications. The most commonly used process capability indices are Cp, Cpk, and Pp, Ppk. Cp measures the potential capability of a process, assuming it is centered, while Cpk measures the actual capability, taking into account the process’s centering. Process capability is an essential concept in quality engineering, as it helps engineers understand the inherent variability of a process and make informed decisions about process control and improvement.

Calculating Process Capability Index

The calculation of the process capability index involves several steps, including data collection, calculation of the mean and standard deviation, and comparison to specifications. The formula for calculating Cp is: Cp = (USL - LSL) / 6σ, where USL is the upper specification limit, LSL is the lower specification limit, and σ is the standard deviation of the process. For Cpk, the formula is: Cpk = min(Cpu, Cpl), where Cpu = (USL - μ) / 3σ and Cpl = (μ - LSL) / 3σ, and μ is the process mean. Understanding these calculations is critical for quality engineers, as they provide a quantitative measure of the process’s capability.

| Process Capability Index | Formula |

|---|---|

| Cp | (USL - LSL) / 6σ |

| Cpk | min((USL - μ) / 3σ, (μ - LSL) / 3σ) |

Importance of Process Capability Index Calculation for Quality Engineers in 2025

In 2025, the importance of process capability index calculation for quality engineers will be multifaceted. Firstly, it will enable them to ensure compliance with regulatory requirements. Many industries, such as aerospace and automotive, have strict quality standards that must be met, and process capability indices are often used as part of these standards. Secondly, it will help in reducing waste and improving efficiency. By understanding the capability of their processes, quality engineers can identify areas for improvement, reducing variability and waste, and thus improving overall process efficiency. Lastly, it will facilitate data-driven decision making. The quantitative nature of process capability indices allows for objective decision making, reducing the reliance on subjective judgments and improving the overall quality of products.

Real-World Applications and Future Implications

In real-world applications, process capability index calculation is used in various industries, including manufacturing, healthcare, and service sectors. For instance, in manufacturing, it is used to ensure that parts are produced within tight tolerances, while in healthcare, it can be applied to monitor the consistency of medical treatments. Looking into the future, the implications of process capability index calculation will be significant. With the increasing adoption of Industry 4.0 technologies, such as automation and artificial intelligence, the ability to monitor and control processes in real-time will become even more critical. Quality engineers will need to leverage process capability indices to ensure that these advanced processes are operating within specified limits, producing high-quality products consistently.

What is the primary purpose of calculating the process capability index?

+The primary purpose of calculating the process capability index is to determine if a process is capable of producing products within the specified limits. It provides a quantitative measure of the process's ability to meet customer requirements.

How does the process capability index impact quality engineering in 2025?

+In 2025, the process capability index will play a crucial role in ensuring compliance with regulatory requirements, reducing waste and improving efficiency, and facilitating data-driven decision making. It will be essential for quality engineers to understand and apply process capability indices to maintain high-quality production processes.

In conclusion, the calculation of the process capability index is a vital tool for quality engineers, providing them with a quantitative measure of a process’s ability to produce products within specifications. As we move into 2025, the importance of this calculation will only continue to grow, driven by the increasing demand for high-quality products and efficient production processes. Quality engineers must understand the process capability index calculation, its importance, and its applications to ensure that their processes are operating at optimal levels, producing high-quality products consistently.