Why Is Understanding Capability Index Formula Crucial For Business Success 2025?

Understanding the Capability Index formula is crucial for business success in 2025 because it provides a quantitative measure of a process's ability to produce output within specified limits. The Capability Index, denoted by the symbol Cpk, is a statistical tool used to evaluate the performance of a process and determine its ability to meet customer requirements. In today's competitive business environment, companies must ensure that their processes are capable of producing high-quality products consistently, and the Capability Index formula is a key metric in achieving this goal.

The Capability Index formula is calculated using the following equation: Cpk = min(USL - μ, μ - LSL) / (3σ), where USL is the upper specification limit, LSL is the lower specification limit, μ is the process mean, and σ is the standard deviation of the process. This formula provides a single number that represents the process's capability, with higher values indicating better performance. A Cpk value of 1.33 or higher is generally considered acceptable, indicating that the process is capable of producing output within the specified limits.

Importance of Capability Index in Business

The Capability Index is essential in business because it helps companies to identify areas for improvement and optimize their processes to achieve higher quality and productivity. By understanding the Capability Index formula, businesses can determine the capability of their processes and make informed decisions about investments in process improvement initiatives. A high Cpk value indicates that a process is capable of producing high-quality output, which can lead to increased customer satisfaction, reduced waste, and improved profitability.

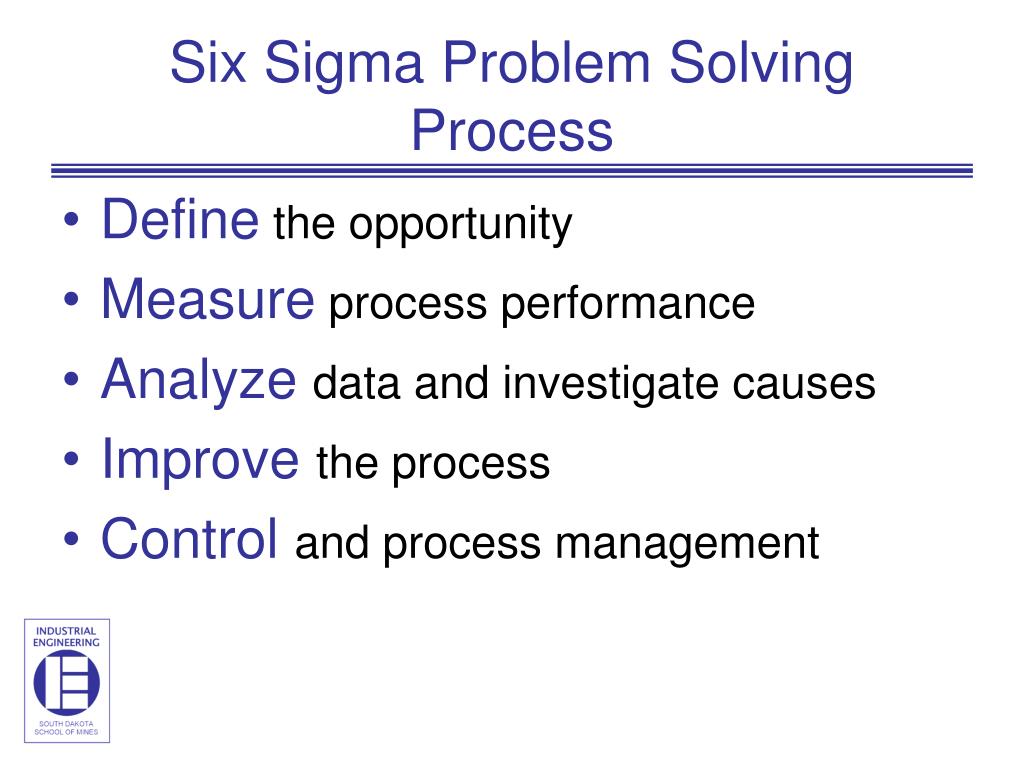

Furthermore, the Capability Index is a critical metric in Six Sigma and Lean manufacturing methodologies, which are widely used in industries such as automotive, aerospace, and healthcare. These methodologies aim to reduce defects and variations in processes, and the Capability Index is a key tool in achieving these goals. By understanding the Capability Index formula, businesses can implement these methodologies effectively and achieve significant improvements in quality and productivity.

Benefits of Understanding Capability Index Formula

Understanding the Capability Index formula provides several benefits to businesses, including:

- Improved quality: By understanding the capability of their processes, businesses can identify areas for improvement and optimize their processes to achieve higher quality.

- Increased productivity: A high Cpk value indicates that a process is capable of producing high-quality output, which can lead to increased productivity and reduced waste.

- Reduced costs: By reducing defects and variations in processes, businesses can reduce costs associated with rework, scrap, and warranty claims.

- Enhanced customer satisfaction: By producing high-quality output consistently, businesses can enhance customer satisfaction and loyalty.

| Capability Index Value | Process Capability |

|---|---|

| Cpk ≥ 1.33 | Capable |

| 1.00 ≤ Cpk < 1.33 | Marginally capable |

| Cpk < 1.00 | Not capable |

Challenges and Limitations of Capability Index Formula

While the Capability Index formula is a powerful tool for evaluating process capability, it has some challenges and limitations. One of the main challenges is that it assumes a normal distribution of the process data, which may not always be the case. Additionally, the formula is sensitive to changes in the process mean and standard deviation, which can affect the accuracy of the results.

Furthermore, the Capability Index formula does not provide a complete picture of process capability, as it only considers the mean and standard deviation of the process. Other factors, such as skewness and kurtosis, can also affect process capability and should be considered when evaluating process performance.

Future Implications of Capability Index Formula

The Capability Index formula will continue to play a critical role in business success in 2025 and beyond. As companies strive to improve quality and productivity, the Capability Index will remain a key metric in evaluating process capability and identifying areas for improvement. Additionally, the increasing use of artificial intelligence and machine learning in manufacturing will require more advanced metrics, such as the Capability Index, to evaluate process performance and optimize production.

In conclusion, understanding the Capability Index formula is crucial for business success in 2025. By using this metric, companies can evaluate process capability, identify areas for improvement, and optimize their processes to achieve higher quality and productivity. While the formula has some challenges and limitations, it remains a powerful tool for evaluating process performance and achieving business success.

What is the Capability Index formula?

+The Capability Index formula is Cpk = min(USL - μ, μ - LSL) / (3σ), where USL is the upper specification limit, LSL is the lower specification limit, μ is the process mean, and σ is the standard deviation of the process.

Why is the Capability Index important in business?

+The Capability Index is important in business because it helps companies to identify areas for improvement and optimize their processes to achieve higher quality and productivity. A high Cpk value indicates that a process is capable of producing high-quality output, which can lead to increased customer satisfaction, reduced waste, and improved profitability.

What are the benefits of understanding the Capability Index formula?

+Understanding the Capability Index formula provides several benefits, including improved quality, increased productivity, reduced costs, and enhanced customer satisfaction. By using this metric, companies can evaluate process capability, identify areas for improvement, and optimize their processes to achieve higher quality and productivity.